150 mm

H 30 mm

1420 g

L 105 mm x B 52 mm

H 12 mm

60 g

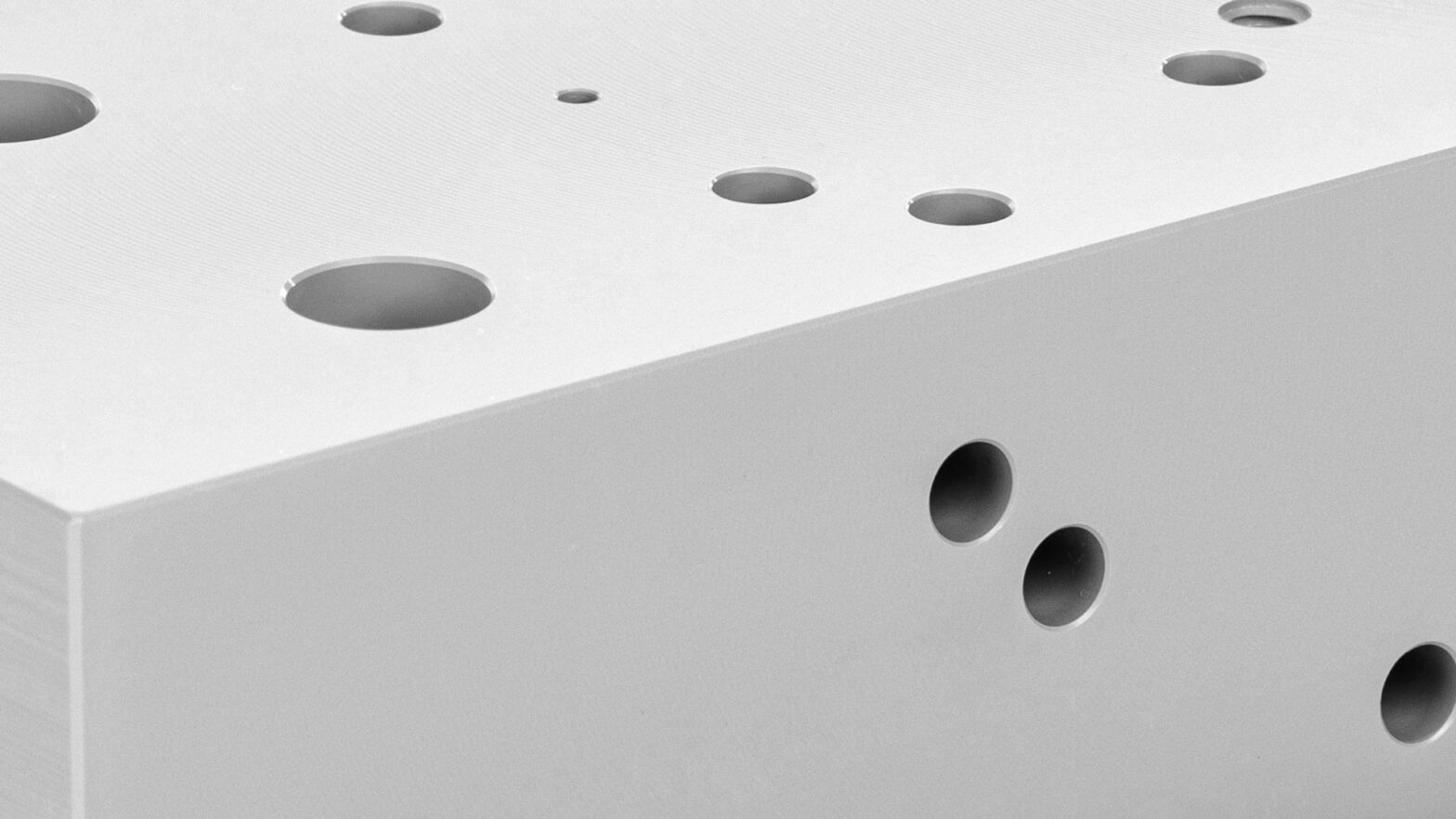

The resilient: tough and non-porous

Coating processes

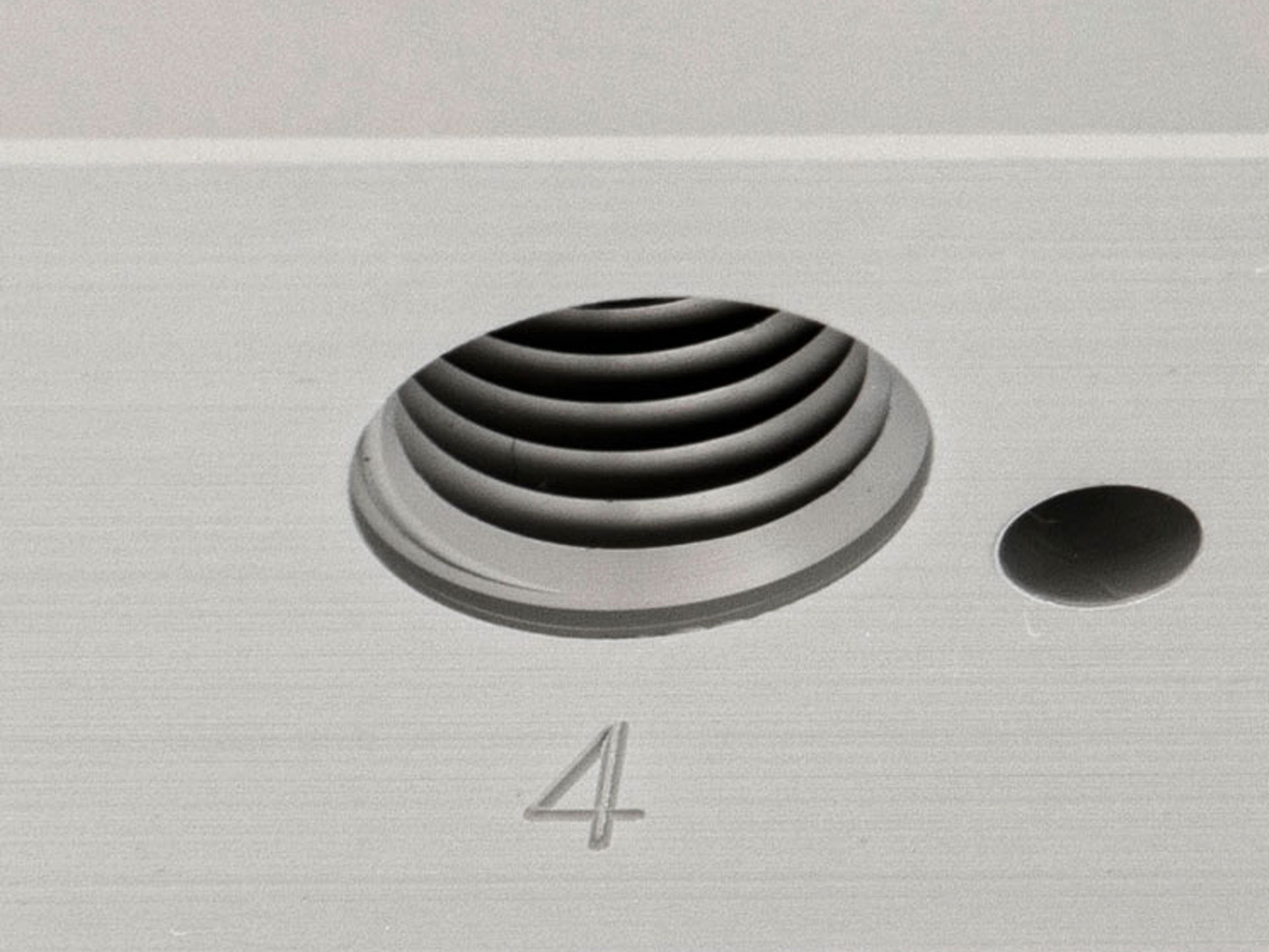

Hard Ematal coating

–

Colours

Intrinsic colour

EMATEC® is an extremely low-porosity aluminium oxide coating containing titanium that is produced through a special anodizing process.

It provides very good protection against wear and corrosion. The minimal coat layer allows production to final dimensions.

Coat thickness and composition

EMATEC® is suitable for coat thicknesses ranging from 10 to 25 µm, depending on the aluminium alloy used. The recommended coat thickness is 15 µm. 80% of this layer thickness ‘grows’ into the base material, resulting in an application of 3 µm.

Tolerance range

The tolerance range of an EMATEC® coat is ± 4 µm depending on the material used and the selected coat thickness.

Intrinsic colour

The colour of a component coated with EMATEC® depends on the alloy, the coat thickness and the type of processing. The colour spectrum ranges from light grey to bronze.

Dyeing

EMATEC® cannot be dyed.

Alloys

Our suitability table provides you with an overview of the aluminium alloys suitable for EMATEC®.

Standards and specifications

There are no corresponding standards or specifications for EMATEC®.