Offer

The right coating for aluminium surfaces

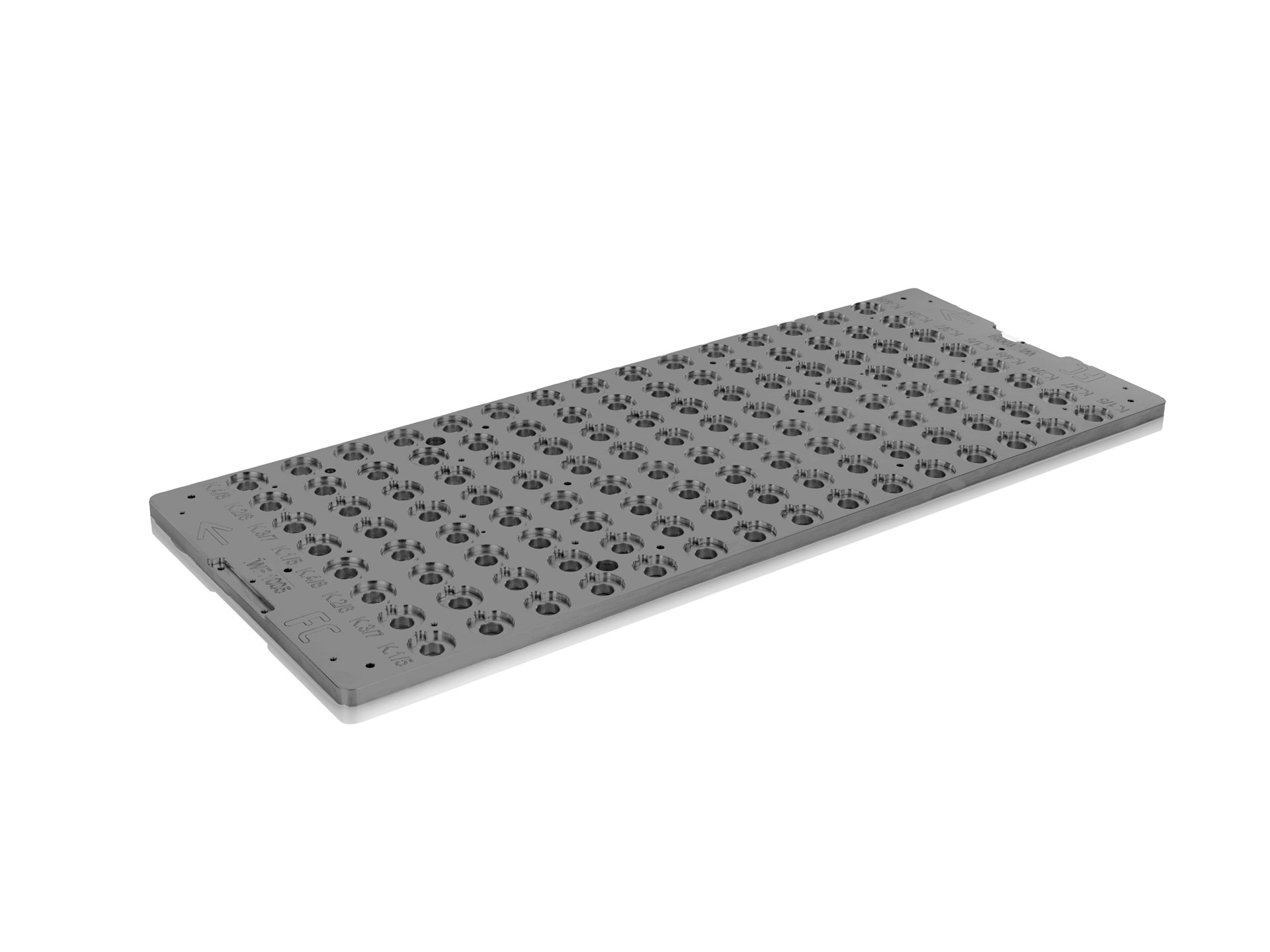

We are specialists for anodising, hard anodising, hard Ematal coating, and bond coating. We coat any aluminium surface with our 6 brands ELOX, ANOTEC®, ALTEF®, EMATEC®, EMATEF® and ANOBOND® partially or completely from 1 mm to 1.5 m or from 1 g to 120 kg since 45 years.

Brands

Coating processes

Anodising

Colours

Transparent

Dyed black

ELOX protects aluminium component from the effects of weather and provides basic protection against mechanical stress.

Coating processes

Hard Anodising

Colours

Intrinsic colour

Dyed black

ANOTEC® provides very good protection against wear and corrosion, and is also suitable for use as a simple bond coat.

Coating processes

Hard Anodising

Coating finish

Teflon® impregnation

Colours

Intrinsic colour

Dyed black

ALTEF® offers excellent protection against wear and corrosion. Its dielectric strength and scratch resistance are unrivalled. The Teflon® impregnation provides additional slip properties.

Coating processes

Hard Ematal coating

Colours

Intrinsic colour

EMATEC® provides very good protection against wear and corrosion. The minimal coat layer allows production to final dimensions.

Coating processes

Hard Ematal coating

Coating finish

Teflon® impregnation

Colours

Intrinsic colour

EMATEF® provides very good protection against wear and corrosion. The minimal coat layer allows production to final dimensions. The Teflon® impregnation additionally increases the slip and non-stick properties of the surface.

Coating processes

Bond coating

Colours

Intrinsic colour

ANOBOND® is an excellent bond coat for vulcanising fluoroelastomers, as well as for adhesives and paints.

There is only one requirement when it comes to coating: Perfection

Not all coatings are created equal. And a promise is only good if it is kept. We are particularly pleased that our name and our 6 brands are synonymous with perfection in partial coating technology and complying with specified coating tolerances. What does this mean for you? You can rest assured that your component is in the very best hands.

Altefco – Your Standard

Our approach

Thinking things through, planning ahead, working together

If you undertake a project with us, our main goal is for you to feel proud of our collaboration, which goes beyond just providing effective service. To achieve this, efficient and effective project management is a central topic. It starts with competent support and technical advice in the early stages of the project and ends with your components being optimally coated according to your requirements.

Our processes are optimised for the best possible result, so there is no idle time, no unnecessary extra costs and no loss of time that repeated prototyping could cause. The advantages of a possible partial coating are already discussed in the product development phase and tolerances are taken into account in a timely manner.

Advantages for you:

You save time and money and benefit from an all-round successful result.

Cleanrooms

On request, we can carry out the final cleaning and packaging in cleanrooms. These components leave our company packed and ready for assembly. This prevents possible contamination during transport or intermediate storage.

Certified

cleanroom

ISO 14644-1:

Class 8